The common assumption today is that robots will soon drive our cars, manage our work, and manufacture our goods. But what is the reality of disruptive innovation in U.S. manufacturing? And how should schools educate skilled labor for this new era?

Globally, manufacturing now accounts for approximately 16 percent of GDP and 14 percent of employment. While the industrial workforce in the United States is up from 11.4 million to 12.3 million, employment is still stuck at historical lows (not seen since the 1940s). More troubling still, labor force participation has been declining since 2009. In fact, over the past three decades, the gap between rich and poor has widened—reversing the prior trend toward a growing middle class.

Discussions on the future of manufacturing are acutely focused on the threat of automation. To be sure, the U.S. manufacturing sector has undergone a turbulent decade. The United States has lost millions of manufacturing jobs to outsourcing. Interestingly, this dynamic now appears to be changing.

Manufacturing is converging (or colliding?) with other industries including software design, virtual and augmented reality, and cloud computing, to name a few.

Disrupting manufacturing

Recent findings from PwC reveal significant adoption in advanced manufacturing technology especially additive manufacturing or 3-D printing. As observers point out, new technology is now moving to upend established markets as costs plunge and quality and performance rise. Adoption rates of advanced technologies suggest that most of America’s factory floors are either already in a disruption cycle—or expect to enter one in the next couple of years. In fact, the scale of disruption in manufacturing threatens to remake the sector as a whole, breaking down barriers to entry.

More than two-thirds of manufacturers are already adopting 3-D printing technology in some way (including prototyping, production of end-use products and experimenting in how they use it). Thirty-five percent of U.S. manufacturers are currently collecting and using data generated by smart sensors to enhance manufacturing/operating processes—and about 40 percent embed sensors in products that enable end-users to collect sensor-generated data. And this is having significant impact on the role of skilled labor.

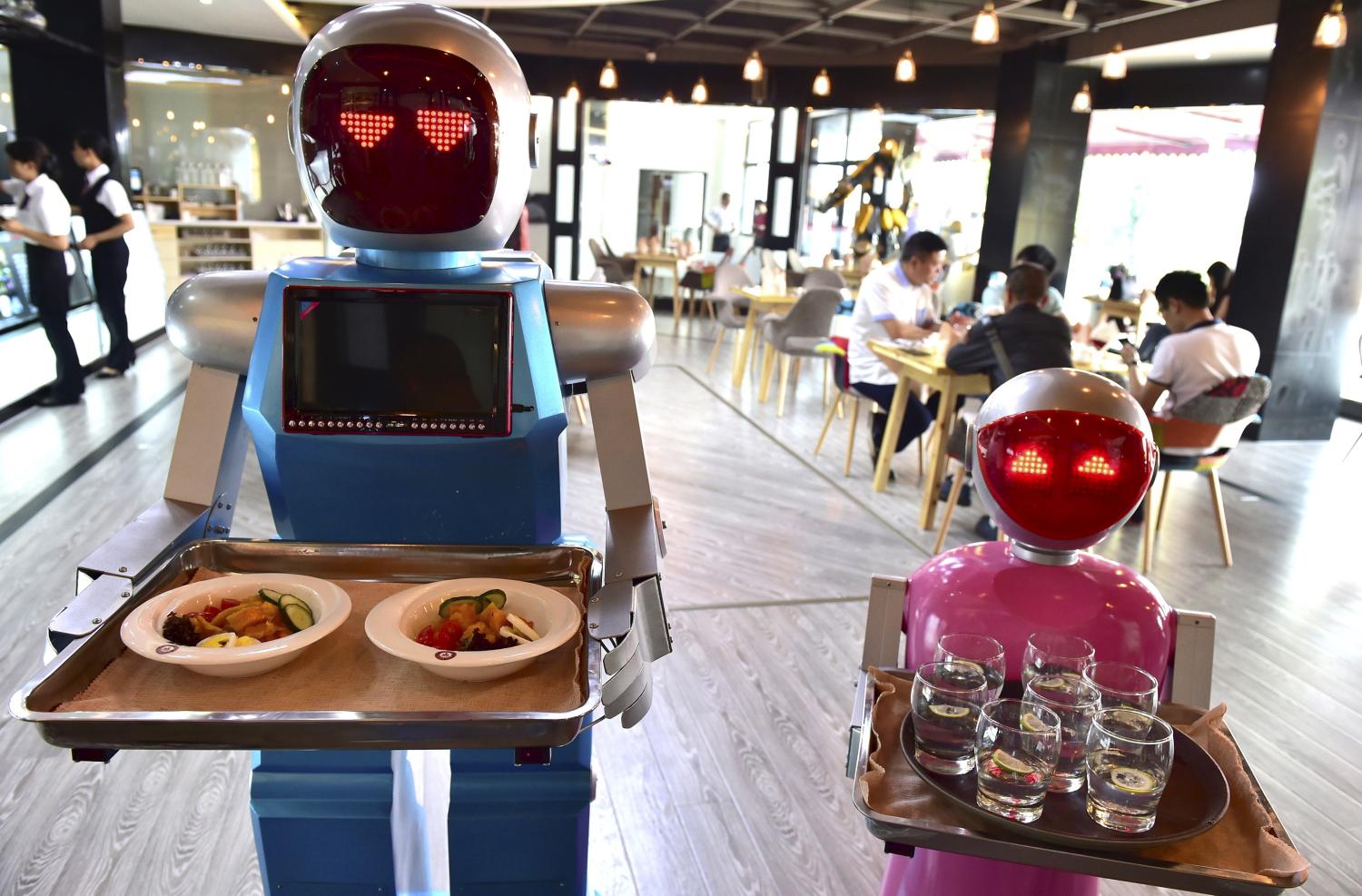

The truth is that fully automated factories are a very real destination for some enterprises. As industrial robots go from being caged and very expensive (and high-maintenance) to affordable and collaborative, six in 10 manufacturers are expected to begin deploying robotics technology across a wide range of tasks (including assembly and materials handling). But there is also a complementary evolution in the processes of manufacturing.

Alongside traditional manufacturing, we are seeing a rising wave of innovation that has the capacity to transform existing markets and value networks. This includes legions of hobbyists and do-it-yourself (DIY) makers who now work in Fab Labs, maker spaces, and the proverbial startup garage. In fact, some of the world’s largest firms are already aggressively campaigning to lure this talent into their ranks.

Education and skilled labor

One of the main challenges with educating young people for this new era is its volatility. As venture capitalist Marc Andreessen observes, software is eating the world.

To be sure, calls to rejuvenate schools in support of advanced skills and capabilities suggest the need for substantial investments in transforming U.S. education. At the same time, the continuous need for talent to drive innovation means that schools could play a major role in the development of new programs that support disruptive manufacturing.

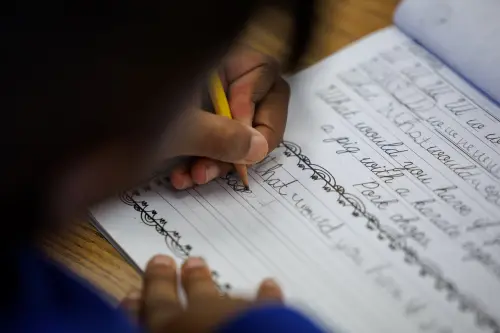

This could include new apprenticeship programs that enable students to directly engage with the making, building, and transforming of ideas and artifacts. In fact, Fab Labs and makerspaces are already emerging in schools across the country and this is a strong sign that local districts are responding to the needs of their communities. These innovation laboratories may well be the platforms we need to develop the next generation of manufacturing talent. And they could offer a window into the future of education as well.

Disruptive innovation is becoming a very real part of the manufacturing industry and this has important implications for how we think about technical education and the education of skilled labor.

General Electric, for example, already hosts maker conferences globally through its GE Garage program, offering training in 3-D printing, robotics, and other technologies. Governmental bodies, such as the federal government’s DARPA, have jumped in, too, spearheading maker-movement and crowd-sourced innovation.

A new generation of inventors is surfing the tide of disruptive innovation and schools will need to adapt accordingly. Indeed, the MacArthur Foundation’s framework for Connected Learning offers some insight into the kinds of project-based learning we should now begin to experiment with.

This learning-by-doing approach has deep roots in education in the form of Jean Piaget’s constructivism and Seymour Papert’s constructionism. Much as the first high schools in the United States emerged in response to a rapidly industrializing 19th century society, so today must schools foster the design thinking and DIY creativity that lends itself to hands-on innovation.

The Brookings Institution is committed to quality, independence, and impact.

We are supported by a diverse array of funders. In line with our values and policies, each Brookings publication represents the sole views of its author(s).