With the slight resurgence of U.S. manufacturing in the recent years—termed a potential “manufacturing moment” by some—it is important to consider not just the future of manufacturing in America but also its geography. Geographic considerations are, in fact, central to whether the slow growth of U.S. manufacturing jobs during the last two years signals a renaissance of American manufacturing or merely a temporary respite from long-term decline.

Watch the Ohio Global Cities Initiative event webcast, where this report was released »

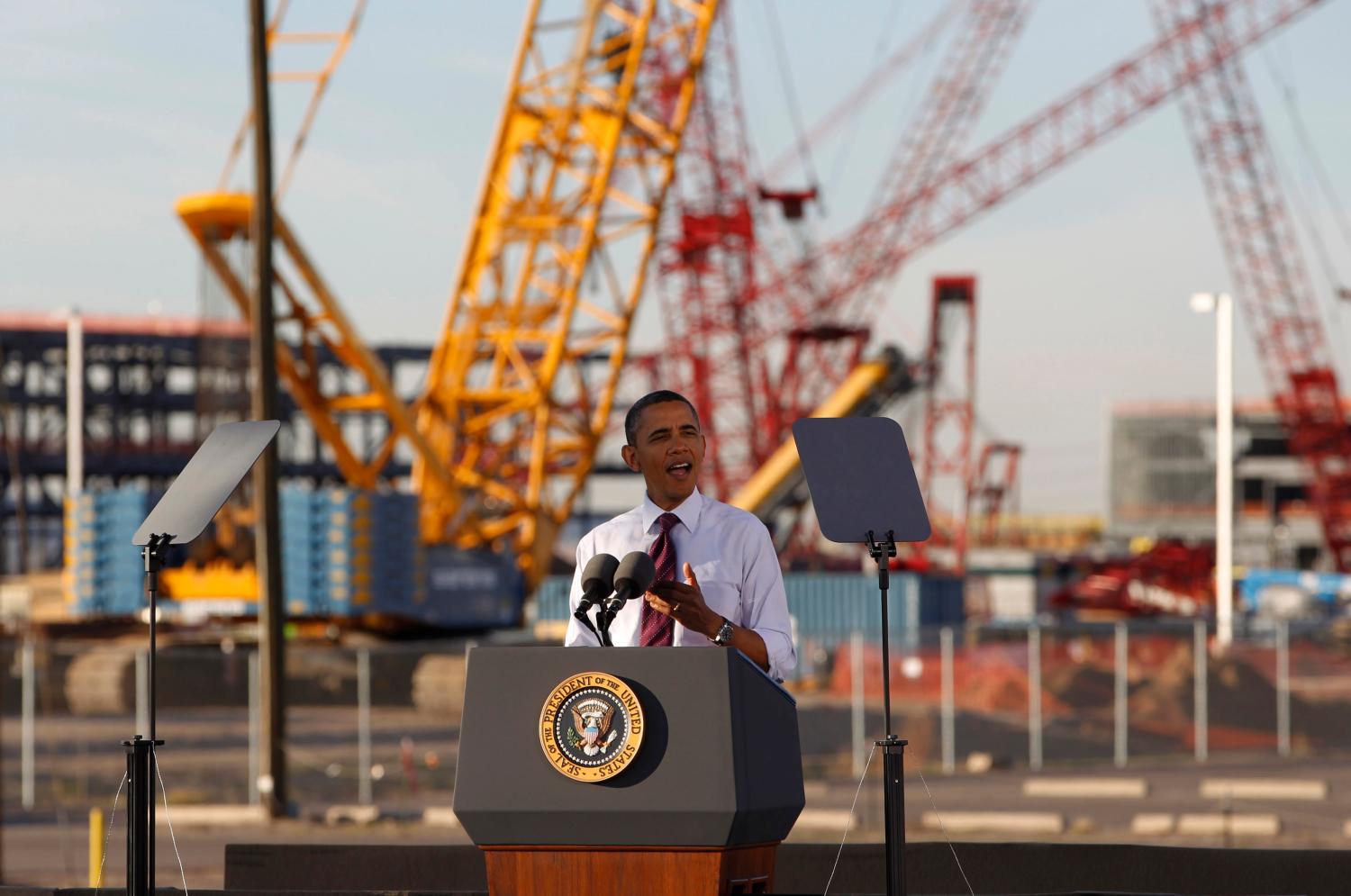

General Electric CEO Jeffrey Immelt recently stated: [T]oday at GE we are outsourcing less and producing more in the U.S. . . . When we are deciding where to manufacture, we ask, ‘Will our people and technology in the U.S. provide us with a competitive advantage?’ Increasingly, the answer is yes.

The people and technology that Immelt sees as crucial to his company’s decisions to increase manufacturing in the United States are place-specific. Those locations—especially metropolitan areas— help create the conditions that give firms such as GE a competitive advantage from manufacturing in the United States.

When firms locate near each other, they gain a number of advantages. The geographic clustering of companies in the same industry or related industries—along with the educational, R&D, business, and labor institutions that support them—promotes high wages and innovation. Such clustering gives manufacturers access to specialized workers, suppliers, and customers and makes it easier for them to share ideas that can improve their performance. Manufacturers can also benefit from their location in a geographic area that has a diverse set of industries, including those not associated solely with manufacturing. In such locations, they can learn from the practices of non-manufacturing industries and gain easier access to such services as engineering, finance, legal services, and management consulting.

These geographic benefits are not simply natural advantages but also advantages created by public policy. The policy approach that aims to create such advantages, often called the high-road approach, encourages firms to utilize highly paid skilled workers to create innovative products and processes. Because manufacturing’s contribution to the nation’s economic well-being is based in part on its high wages and innovative capacity, high-road policies are in the national interest. High-road policies should have an important geographic component if manufacturing differs in important ways in different parts

of the nation and if clustering and diversity are important for manufacturers. Geographic high-road policies build on the strengths that come when firms locate near each other.

It is a common belief that manufacturing is basically the same throughout the United States, that it has completely decentralized from its historic central locations, and that this decentralization matters little to the productivity of manufacturing firms. For example, Christina Romer, former chair of President Obama’s Council of Economic Advisers, recently claimed that geographic clustering is not especially important in manufacturing. This report shows that such views are incorrect. American manufacturing is highly differentiated geographically. Different regions of the country, different metropolitan areas, and even different counties within the same metropolitan area differ greatly in their manufacturing industries, technology levels, wages, and plant sizes. Moreover, groups of manufacturing industries cluster systematically in different types of metropolitan areas.

Geographic high-road policies are easier to implement if manufacturers are already moving toward locations that offer the benefits of clustering and diversity and away from those whose competitive advantage is based largely on low wages. Here, this report suggests, the evidence is mixed. The report shows that manufacturing jobs have, for several decades, been moving out of the dense, centrally located metropolitan counties that provide manufacturers with the greatest benefits of diversity. Yet it also shows that the flight of manufacturing jobs to the right-to-work states of the South has at least temporarily halted.

In its totality, this report offers the first comprehensive analysis ever of the metropolitan geography of U.S. manufacturing.

The report begins by situating the present moment of U.S. manufacturing. It continues by reporting a series of often surprising descriptive trends affecting the nature and location of American production. Finally, it concludes by proposing geographic high-road policies for American manufacturing. These policies require a federal platform that is sensitive to the ways in which manufacturing differs geographically. They require state and local decisionmakers to take the lead in adapting the high-road approach to their specific needs. This policy prescription differs from the general business attraction incentives that have dominated state and local economic development policy. These incentives (which cost state and local treasuries $70 billion annually) are problematic because they reduce the revenue available to fund investments in training and technology—investments that are essential to a high-road approach.

The Brookings Institution is committed to quality, independence, and impact.

We are supported by a diverse array of funders. In line with our values and policies, each Brookings publication represents the sole views of its author(s).